The World Lighthouse Hub

H16: Vapourised Paraffin

Q: How was vapourised paraffin used in lighthouses?

Fig. H16.1 A magnificent photograph of the recently renovated vapourised paraffin light source at Vlaming Head Australia. (Reproduced with permission)

For many years, lighthouses created light by the combustion of vapourised oils such as paraffin. The principles are:

Storage tanks somewhere on the station - in the yard or in adjacent buildings;

Feeder tanks inside the tower close to the light;

Pressurising system - usually a hand pump - to create pressure in the system that delivers a supply of fuel to jets or nozzles. The fuel exits the jets in a fine aerosol form, an intimate mixture of fuel and air, which is much more combustible.

During the development of this method, there were many variations on design intended to optimise the light generated compared to the fuel consumed. (Economics has long been a major consideration in the operation of lighthouses. They had often been built for profit by entrepreneurs and the balance of expenditure on fuel and keepers wages had to be weighed against the possible income from light dues.) Besides the supply of fuel to the wicks, this had to be achieved by the supply of the right amount of air for optimum combustion.

The following additional material is taken from sources indicated.

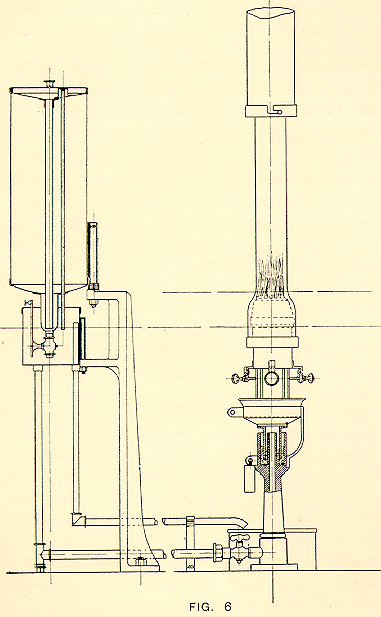

The constant level (gravity) type (a) gives comparatively high candle powers, and is for use in large lights, but has now been practically superseded by the incandescent oil burner, and is seldom supplied except as a "Stand-by" to the latter. [Chance Bros and Co, 1910 Guide\Chance fig6.jpg]

Oils came from many sources of both animal and vegetable origin and could be crude or refined. Vegetable sources included olive and rape seeds which were crushed to provide the oil. Herrings and other fish could also be used to make oil, the source used depending upon the availability of supply. Whales were for many years a major source of oil, especially the sperm whale.

As with coal fires, the technology was entirely focused on getting the maximum brightness from the flame for the minimum amount of smoke and consumption of oil. The first oil lamps were equivalent to a few candles in light intensity. Most importantly, they were less work that candles of equivalent light intensity.

In our colonial Lighthouses other varieties of oil are used, of which one need only be noticed as being used in the Lighthouses near the Cape of Good Hope. This oil is procured from the tips of the tails of the Cape sheep, and is said to be far superior to any other oil for brilliancy of light; but the quantity consumed, and the expense, are great. It costs 10s. 6d. per gallon, and the first-order light of Cape Agulhas consumes about 730 gallons a-year; 482 gallons of rape-seed oil would be necessary for a year's supply. [Findlay, 1862, Ch. III]

One great advantage in the refined rape-seed oil is that it does not thicken, except upon a very great degree of cold, a qualification which places it far above sperm and many other oils for winter use. Indeed the change is a fortunate one in another respect. The untiring perseverance of the whale-fishers from the neighbourhood of Nantucket has so dispersed and destroyed their prey, that it is almost doubtful if a continuous and sufficient supply could be maintained, except at great prices. [Findlay, 1862, Ch. III]

The essential components were a container known as a reservoir to store the fuel and a wick which dipped into the oil. The wick became saturated with oil and the capillary effect acted to draw the oil upwards to the end of the wick where it fed through a metal burner. At this point, the oil evaporated, mixed with the air and formed a combustible mixture which could be ignited with a match. Thus it was that the oil was consumed and although the wick was a necessary part of the combustion process, it only burned itself very slightly.

Fig. H16.2 The term Lamp, as opposed to burner, usually refers to the portion of the illuminating apparatus which contains the oil, for instance: A Constant-Level Lamp, which automatically regulates the supply of oil to a wick burner. [Chance Bros and Co, 1910]

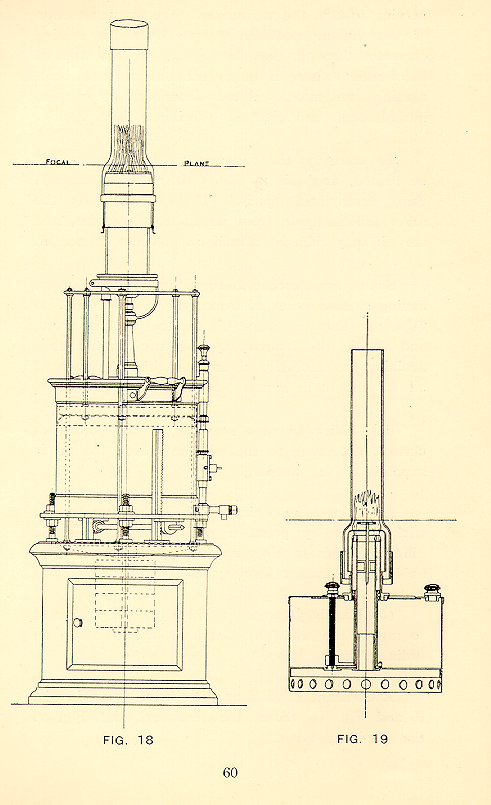

These incandescent oil burners are now generally made in three sizes, the diameter of the mantles being 35 m/m, 55 m/m, and 85 m/m respectively, the different sizes being suited to the different diameters of the Apparatus in which they are to be used. The diagram shows the 85 m/m type. A burner having a group of three mantles is also made, mostly for use in large Fixed or Occulting Lights. [Chance Bros and Co, 1910]

A Capillary Lamp works on the same principle as an ordinary house lamp; in this case the lamp and burner -are practically one, and it is therefore called by either name, though strictly speaking the burner is that part which holds the wick or wicks. [Chance Bros and Co, 1910]

The most important illuminant is oil used in conjunction with an incandescent mantle. The method of working is briefly as follows : The oil contained in a suitable air-tight vessel is put under an air pressure of about 65 lbs. per square inch (5 kilos per square cm) and by this means is forced through a small copper tube up to the burner, where it passes through the vapourizing tubes, which are heated from below, and is gradually turned into vapour. At the end of these tubes it passes through a very fine hole in the "nipple" in the form of vapour, and draws air with it through a larger tube to the mixing chamber. Here some of it is turned aside and passes down to the Bunsen tubes where it burns, serving to heat the vapouriser. The greater portion of the vapour however, passes from the mixing chamber through the wire gauze at the top of the burner, where it burns with an intense heat, causing the mantle placed around it to become incandescent, and give off a brilliant light. [Chance Bros and Co, 1910]

As in Antiquity, a lighthouse consisted usually of a stone tower burning wood, coal or torches in a grate on its summit in the open air, or of a tower or pole on which a keeper hoisted an iron basket containing burning coal or pitch. Sometimes moveable or built-in lanterns with windows of horn or thick glass protected oil lamps or candles. The cost of maintaining these lighthouses was often considerable: stocks of fuel had to be obtained and transported, and attendants had to be paid for the arduous task of keeping fires bright by stacking, stirring and blowing during the night and for frequent trimming of the wicks of oil lamps and snuffing of candles. The oil lamps, smoky and difficult to regulate, unless one were content to show only a tiny flame of which the total light value was small, bore little resemblance to the lamps introduced in 1782. The candles also differed greatly from their modern types. In northern Europe, where the nights of summer were short, the fires were not kindled for several months of the year. [Stevenson, 1959, p17]

Wick burners may be divided into two classes, according to the way in which the oil is supplied to the burner. (a) Those in which it is forced up to the wicks either by pressure put upon it, as in the different types of Pressure Lamp, or by Gravity, as in the constant level type. (b) Capillary lamps in which the oil is caused to mount the wicks by Capillary action as in an ordinary house lamp. [Chance Bros and Co, 1910]

The oil is made to flow into the burners by various means. Fresnel's invention consisted of a series of four small pumps, worked by clockwork, which forced the oil upwards to the flames. Another mode was by weights acting on a piston; a third by a spring doing the same office, a plan which has since become in universal use in the moderator lamps. Another mode, the pneumatic lamp of Messrs. Wilkins, acted by means of the pressure of air in the reservoir; and another, frequently applied of late, is by placing the reservoir slightly higher than the lamp, the oil thus flowing freely by its own gravity to the required level. [Findlay, 1862, Ch. III]

The capillary lamp (b) is used for small lights, and from its simplicity needs little description. Burners of this type are made with either one or two wicks, preferably circular, and giving 25 and 50 c.p. respectively. [Chance Bros and Co, 1910]

Fig. H16.3 The constant level (pressure) type of oil lamp is shown here. [Chance Bros and Co, 1910]

With our incandescent installations, three complete burners are supplied. The keeper should always have one in readiness to substitute for that in use if necessary, and if he cleans the burners and tubes properly, it should never occur that all three are out of order. Should it be necessary, however, that he has at a moment's notice to bring the stand-by into use, a capillary lamp, though it does not give such a high candle-power, can always be started at once, while to bring a comparatively complicated form of stand-by such as a pressure or constant level lamp into action, necessarily takes some little time. It is of course most important that the light should be out for as short a period as possible, and this appears to us such a strong factor that in view of the very probable delay mentioned above, we recommend the adoption of the simpler type as a stand-by. [Chance Bros and Co, 1910]

A device specifically designed to allow the combustion of oil for a light source in a lighthouse. There was no standard design of lamp, although there were some designs that provided steps forward in the technology of lighting beacons more efficiently and reliably.

Oil is a liquid fuel used for burning (combustion) in a lamp. It was greatly used to provide a light source in a lighthouse. Just as there were many different types of oil, so there were many more types of lamp to burn it.

Candles were considered to be rather better than oil lamps in terms of ease of transport and storage of supplies, but candle lights were more expensive to maintain.

A wick is a material woven into cord, string or sheets of fabric that can then be incorporated into a burning deice such as a candle or an oil lamp. The wick does not burn well itself, but soaks up a liquid fuel and aids evaporation of that fuel so that it can be set on fire and a light produced. Wicks of candles needed to be trimmed frequently so that they burned regularly and reliably. When they did not, the process was called, guttering.

Burning torches (or flambeaux) were often used to aid lighthouse construction in darkness, but were almost never used in lighthouses. A torch was made with linen or other woven material soaked in a fuel such as oil, which could be set on fire to provide a light source.

The material used as a fuel to produce the light is an illuminant. Examples of illuminants are candles, coal, torches and pitch fires, wood, oil, kerosene (paraffin), gas, electricity.

To start up, the vapourizing tubes must first be heated, and this is done with a small burner, using methylated spirit. This should heat the tubes sufficiently in from six to eight minutes, and the oil may then be turned on and the burner lit. Such incandescent burners are suited for oil having a flash point of from 1450 to 1600 F (620 to 710 C), so that the same oil can be used in them, and also in the ordinary type of wick burner, thus avoiding the necessity of storing different kinds of oil for the main burner and the stand-bys. [Chance Bros and Co, 1910]

1100 After the passing of the Dark Ages, sea-lights were established anew in Europe, commencing about 1100 A.D. at the entrances to Italian ports. Their illumination was given by oil lamps or candles sheltered in lanterns but in northern Europe coal fires burning in the open were preferred. Contemporary accounts of the tall Lanterna of Genoa, lighted in encouraged the establishment of more lighthouses throughout Europe. Before 1586 the navigable channels of Dutch and German rivers were marked by beacons and buoys which by shape and colour directed ships to port or starboard. [Stevenson, 1959, p17]

1350 A lighthouse is established at Travemunde for the port of Lubeck. The tower still exists. Recorded as lit by fire in 1539 and oil in 1700. [Hague, 1975, p22; Zemke, 1982, p13.]

1544 A light known as the Lanterna is built at Genoa, replacing a medieval tower. Two pillars 10 m and 7 m square, each over 35 m high, were set one upon the other to form the present tower. Oil lights were used for the first time in 1778. Records from the 17th century show it to carry an excellent lantern in which, from time to time, experiments with lamps, wicks and glazing were carried out. It was in use in 1959 and dominates the harbour as the tallest brick or masonry lighthouse in the world at 75 m height. Hague, 1975, p21; Stevenson, 1959, p18

1550 An explorer from western Europe, crossing to Asia Minor observed in the Bosphorus a navigation light contained in an octagonal tower with small windows which he described as of "christian design", the glasses being jointed with lead. We assume this to be the Constantinople lighthouse. He warned navigators to beware of false or misleading lights with similar aspect that were set up occasionally by wreckers elsewhere in the vicinity. In 1595 another traveller described the same lighthouse as "a turret of stone 120 steps high having a great glass lanthorne in the top, four yards in diameter and three in height, with a great copper pan in the midst to hold oil, with twenty lights in it. [Stevenson, 1959, p19]

1566 The magistrates and council of Aberdeen decided to re-erect a hand lantern in the east gable of St. Ninian's chapel on Castlehill. It was to contain 3 oil lamps and was to be lighted from 1 September to 31 March each year. To pay for it, the Council instituted an elaborate scheme of taxes on ships and lighters ferrying goods between ship and shore, and on goods imported and exported. They also appointed a person to collect the fees. [Munro, 1979, p23; Stevenson, 1959, p20]

1690 Remarkable improvements in lighthouse structures and lighting were achieved in the period 1690-1782. In England, the first towers exposed directly to wave-action were erected on the Eddystone Rocks, a piled beacon was set on the Smalls Rocks, and lightships were moored at sandbanks; in Sweden, parabolic reflector lights, oscillating lights, and ultimately in 1781 the world's first revolving light were exhibited to the mariner. The number of coal-fire beacons reached its maximum but oil lamps served the majority of sea-lights. North America established its first lighthouse, probably in 1716. [Stevenson, 1959, p45]

1700 Fifteen major navigational lights exist in Britain, of which 12 are coal fires. Of the five main lighthouses on the French Atlantic coast, one burned wood and one burned oil. In Sweden, four out of the five exisitng lights burned coal. [Stevenson, 1959, p273]

1716 The lighthouse established on the small island of Little Brewster off Boston, Massachusetts, in 1716 is the earliest sea-light to be recorded in America. Its tall masonry tower of excellent design carried a glazed lantern containing oil lamps. It is described in Section XI. [Stevenson, 1959, p45]

1774 A test is carried out to compare a coal fire with an oil light fitted with a parabolic reflector by Hutchinson. The coal fire was preferred because at that time the oil lamp was too focussed and could not illuminate a big enough part of the horizon. Stevenson, 1959, p273

1776 After fire destroyed the rear lighthouse at Hunstanton in England about 1776, the tower which replaced it was topped by a glazed lantern containing one reflector with an oil lamp instead of the coal fire. An account of 1781 says that the 'light is thrown out by a lamp of oil which plays upon a great variety of pieces of glass artfully disposed, by which the flame from the lamp is multiplied and reflected and is to be clearly distinguished at sea at a distance of seven leagues. By this construction the light is constant and certain, whereas the seamen were sometimes obliged to awaken the old gentleman at the former lighthouse with a shot, to put him in mind his fire wanted blowing.' Ezekiel Walker, a philosopher of Lynn, designed this reflector light but his numerous scientific papers do not include a reference to the subject. It is unlikely that he was unaware of Liverpool's earlier use of reflectors for sea-lights. Bearing in mind the type of reflector which Thomas Smith produced in 1787 after discussions with Walker, one might assume that the Hunstanton reflector was parabolic and formed of facets of mirror glass set in a plaster mould. This accords with the description of 1781. [Stevenson, 1959, p54]

1777 A Minute of the Elder Brethren of Trinity House dated 2nd August 1777 records that they 'ordered that a reflector be made in London and put up at Lowestoft by way of experiment, and the opinion of persons concerned in navigation be collected'. A contemporary local account states that at the upper lighthouse they discontinued the coal fire and fitted in its place a glass lantern 7' high and 6' in diameter within which a cylinder covered with 4,000 small mirrors reflected the light from 126 oil lamps: the light was brilliant and visible 20 miles to sea. In 1778 a London newspaper gave prominence to 'a very ingenious contrivance' lately finished by cabinet-makers in Aldersgate Street as a substitute for the fire grate on top of a lighthouse. In the centre of a large lantern of iron and brass they set a cylinder as a reservoir for oil which flowed through pipes to a horizontal circular hollow tube, placed midway between the cylinder and the lantern panes, and containing many oil burners. Probably wicks projected from holes in the top of the tube. The central cylinder was 'covered with small square mirrors fix'd close to each other; by which means such a Magnificent light is reflected as will (it is supposed) be seen twenty miles at sea. A very considerable expense will be saved by the above contrivance as, it is said, a gallon of Oil will be equal to three Chaldrons of Coal...the Effect is Amazingly Grand'. It is difficult to resist the conclusion that the reflector light tried by Trinity House at Lowestoft was this apparatus or a similar contraption. Mariners would soon recognise the futility of this sparkling affair. Apart from the difficulty to the lightkeeper of managing so many lamps, practically no light would be directed usefully to shipping. The twinkle of the numerous mirrors would be bright and attractive in a confined space but the rays of light which they reflected would be dissipated in all directions, upwards and downwards. The tiny pieces of mirror served merely as spangles and a better result would have been obtained at the lighthouse if they had been removed and the lamps alone clustered in the centre of the lantern. [Stevenson, 1959, p56]

1780 In full blaze, a good coal fire was better for navigation than any other form of unmagnified lighting. Coal fires declined in use after 1780 when the use of parabolic reflectors with oil lamps was understood and used to produce even better lights.

1782 Hitherto, all oil lamps and candles in use at lighthouses, besides requiring trimming several times nightly, gave out smoke which, though sometimes invisible in the air, was deposited ultimately on the mirrors and lantern panes as a film of soot consisting of particles of unburnt carbon, which resulted from imperfect combustion due to lack of oxygen or air in the hot portion of the flame above the wick. Ami Argand, a scientific philosopher born in Geneva in 1755, discovered a cure for this trouble and evolved a comparatively smokeless oil lamp which gave a steady flame and a more intense light than was obtainable previously. His invention improved lighthouse illumination and soon brought immense social and economic benefit to western Europe. The special feature of Argand's lamp consisted of two vertical concentric tubes of thin brass, about 1" in diameter and separated slightly, the space between them holding a cylindrical cotton wick. Air passed upwards through the inner tube as well as outside the outer tube and this double air current playing on both sides of the lighted wick ensured an even temperature and good combustion of the oil. A part of the complete lamp that assisted combustion was a circular glass chimney closely surrounding the outer tube and the wick. Discovery of its advantage was accidental. Argand's brother was reaching across a table for a broken neck of a flask which he happened to place over the lamp flame. 'Immediately it rose with brilliancy. My brother started from his seat in ecstasy, rushed upon me with a transport of joy and embraced me with rapture.' Argand is credited also with adding a screw to alter the level of the wick. A further development made by Lange, one of his rivals in improving lamps, was a contraction of the chimney above the wick, which drove the air inwards to the flame, giving an even more intense light. By about 1815 the lamp gave light worth 7 to 8 candles. An improvement after 1820 was a spreader, a small metal piece shaped like a mushroom or a circular T, which was set above the centre of the tubes and below the chimney contraction. This drove the flame outwards towards the glass and increased the combustion even more. About 1840, when the lamp with its single circular wick had received all these improvements, its power was rated at 10 candles. Argand made his discovery about 1781 while seeking to improve the lighting of a distillery which he had established near Montpellier in France. In 1783 he took his lamp to Paris, hoping to arrange for its manufacture on a large scale. There he assisted the Montgolfier brothers in their famous balloon trials: they thought that the lamp would provide heating during the air-flights. Several of Argand's companions in this enterprise afterwards claimed some of the credit for perfecting the lamp. In 1784 he brought a specimen lamp to London and arranged for its production in England by a manufacturer named Hunter, and in 1785 he began to make lamps at Gex in France. When his workshops were destroyed during the French Revolution of 1789 he retired to Geneva and occupied himself with designing reflectors suitable for lighting streets, factories, churches and houses. The success of these double-air-current lamps in France and England increased the demand for sperm oil after 1784 and whale-hunters suddenly found prosperity. But the Revolution and the subsequent wars with Britain soon cut off the supply of that oil to France and ruined her fisheries, and recourse was had to colza oil obtained locally from crushing the seeds of a wild cabbage. The outcome was surprising: cultivation of this plant on an increasing scale proved of great benefit to French agriculture. The only adjustment required in the argand lamp, in changing from sperm to colza oil, was a thicker wick. After 1845 colza oil was introduced into the British lighthouses as being the most suitable oil for their lamps. Despite assistance from influential friends, Argand failed to get adequate protection for his wonderful invention and Quinquet and other lamp-makers in France produced lamps to his design from which no financial benefit accrued to him or his family. A petition presented to the British Government in 1793 suggested that he should be rewarded: it had been signed in England by 10 firms interested in the whale-fisheries, by 8 proprietors of workshops which profited from making his lamps and by George Robinson pourvoyeur et surveillant of sea-lights to Trinity House and Greenwich Hospital. But a grant was not forthcoming and Argand died in poverty in Geneva in 1803. The petitioners declared that Argand's invention prevented shipwrecks on dangerous coasts, as only by using his lamp in a reflector could excessive smoke be avoided and a strong beam of light be obtained. Argand lamps were first adopted for lighthouses by Trinity House at Portland in 1789 and by 1820 they had been installed at some 50 coastal lighthouses in Britain and Ireland, but at few lighthouses elsewhere. They were in use at many lighthouses about 1880 but wick lamps are found now at only a few lighthouses and these are of little importance. [Stevenson, 1959, p62]

1782 The invention by Argand in 1782 of an oil lamp which gave a steady smokeless flame was one of the most important events in lighthouse history, though only in England was this lamp used before 1800 in its proper form for sea-lighting. In this period England and Scotland adopted parabolic reflectors as the standard illumination of their coastal lighthouses; France, England and Ireland introduced revolving lights of considerable power; and England and Ireland fitted lens lights. [Stevenson, 1959, p61]

1796 The aim of the design of oil lamp instituted at boston was that smoke would find a direction to escape at the top of the lantern. During one night, the burning of the 16 wicks reduced the level of the oil in the reservoir by 2 ins (50 mm). However, in 1796, an inspector reported that the lantern was full of smoke and that it was painful for a person to stay in the lantern for any period of time.

1800 Whale oil from Greenland was known before 1550 as train oil (from the Dutch traen) and was a major fuel for a long time. It cost 3 shillings per gallon in 1800 and began to be replaced in England by spermaceti oil.

1810 Winslow Lewis, an unemployed ship captain, persuaded the US government to adopt his Argand lamp and parabolic reflectors instead of the spider lamps previously used throughout the US. At a public exhibition at the Boston light tower in front of government representatives he showed that not only did his device produce a brighter light, but it used less oil. This proved to be a short lved success for at about the same time, Fresnel was inventing his lens system - one that was far superior and is still used to this day, but the US government continued to used the Lewis system, choosing to ignore the advantages of the Fresnel system. Consequently, the US lagged behind in technology for many years. [Holland, 1972, p14]

1812 Nevertheless, the Boston design lamps remained the principal method of illumination in the US lighthouses until the introduction of Winslow Lewis's lamps and parabolic reflectors in 1812.

1819 About this time, most lightships showed either two or three fixed lights from candles or oil lamps in lanterns as the best distinction from the lights of other vessels, all under 5 candle power. Stevenson, 1959, p281 Guide\Chance fig20.jpg

1822 To improve his original design, Argand tried using concentric wick arrangements but the excessive heat produced damaged the metal burner tips which held the wicks and boiled the oil. By 1822, in association with Arago, Argand had devised three and four concentric wick lamps that had the equivalent of up to 200 candles.

1823 The use of coal fires has not been so long abolished as might be imagined. In Britain they were used till 1823. Thus the Isle of May Lighthouse, at the entrance of the Firth of Forth, had a coal fire till 1810; at St. Bees Head, Cumberland, oil was first used in 1823; at the Flat Holm, Bristol Channel, in 1820, [Findlay, 1862, Ch. III]

1823 The last lighthouse in Britain to use coal, St. Bees, is converted to oil. [Stevenson, 1959, p273]

1846 The fuel used in the English Lighthouses in these excellent lamps up to the year 1846, was the best sperm oil that could be procured. At that period a change was made throughout the whole of the lamps, by adapting them to the use of colza or refined rape-seed oil, requiring a thicker wick. This oil was in use in the French Lighthouses for some time prior to this, and was procured from the seed of a peculiar species of wild cabbage, known in the north of France under the name of colzat, or colza. This plant is extensively cultivated in Normandy, &c., the chief markets for the oil being Caen, Rouen, Lille, and Courtrai. [Findlay, 1862, Ch. III]

1847 The oil now used by the Trinity House is chiefly refined by a patent process. This refined oil is of a superior character to the sperm oil; it produces a brighter flame, does not cause so much deposition on the wick, consequently, will burn longer without trimming; any adulteration in it is much more easily detected than in sperm oil, and it is half the cost. It is an excellent substitute for the oil, which is annually becoming dearer, and more open to being mixed with other and inferior oils. In the Liverpool lights olive-oil has been used since 1847 - a change effecting a saving of 40 per cent, on the use of sperm-oil. [Findlay, 1862, Ch. III]

1855 One of the last recorded uses of wood as an illuminant occurred at Kamchatka. They were replaced by oil lights. [Stevenson, 1959, p271]

1860 This beautiful adaptation (electricity) was used for 6 months in the upper Lighthouse of the North Foreland, and was very successful. The light, which is not 1/4 inch in diameter, was shown to disadvantage in the great lens, which, being adapted for the great lamp, was not suitable for it, and appeared at a distance of a bluish colour, probably by contrast with the red or yellow flame of the adjoining oil lamps. It is to be tried at the Dungeness Lighthouse. The totally distinct character and colour of the electric light, will at once distinguish it at any distance from that derived from any other source. Therefore, supposing that this illumination be adopted as an adjunct to that in present use, the stations in which it is applied will be distinguished from their neighbours without the chance of mistake, the fruitful source of accident from the present lights. [Findlay, 1862, Ch. III]